iba System - See The Big Picture

The iba System for process data acquisition and analysis consists of perfectly adjusted hardware and software components for acquiring, recording, analyzing and processing measurement data. Due to the modular design and the simple configuration, the iba System can be adapted comfortably to the various tasks and is scalable in size at any time.

“With the iba System you receive the greatest possible clarity about all technical processes.”

Dr. Ulrich Lettau, CEO, iba AG

Business Benefits

Enhanced

productivity

Reduced

plant downtimes

Improved

and documented product quality

Saved

energy and raw materials

Prevention

of critical plant conditions

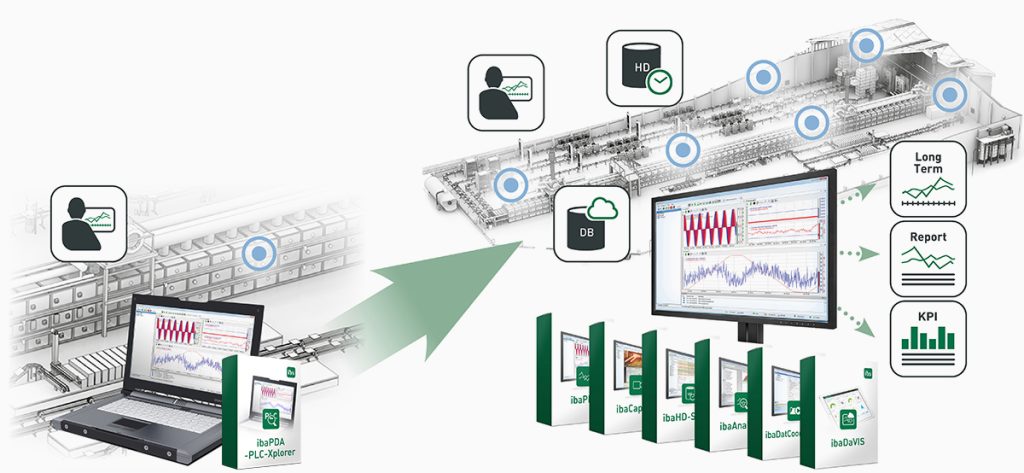

Autonomous, modular, scalable

Our data acquisition and software solutions for measuring, validating and analyzing machine, production and energy plants are scalable and can be perfectly extended at any time. They can not only grow along with increasing requirements but also get along with all common industrial control systems.

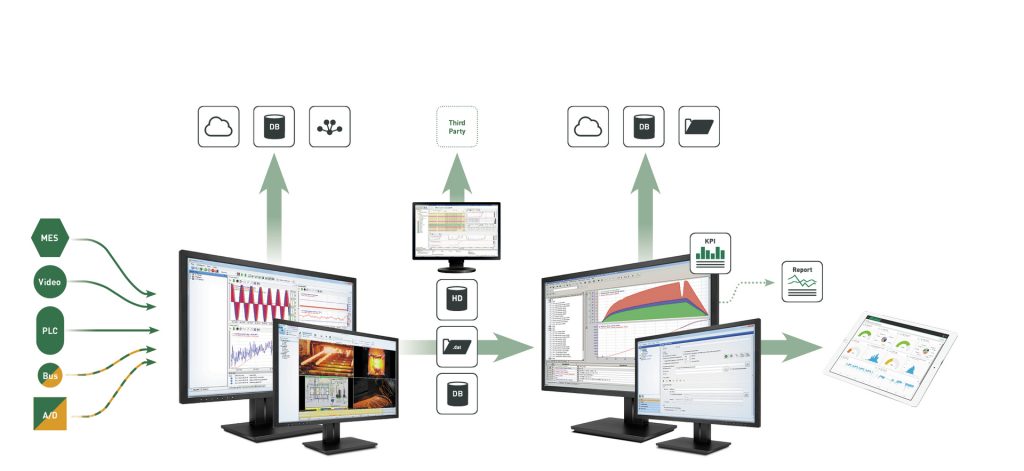

Process Connectivity

Acquire & Record

Analyze & Optimize

Output Connectivity

Scalable at any Time

Apart from its comprehensive connectivity, scalability is another main feature of an iba System. It is extendable at any time and can grow with increasing requirements. Starting from troubleshooting of a PLC with 64 signals to monitoring of a large plant with over 100,000 signals, camera systems with machine vision applications and quality data loaded into databases for automated product release and other features.

Data Acquisition

Data acquisition with iba can exactly be customized to your situation and aims. You only configure those interfaces and signals which you need for capturing your process. This allows you to start on a small base and add further interfaces, signals, data stores or camera systems, when your requirements grow.

Data Analysis

At the beginning, analysis in general is interactive and signal-oriented. Nonetheless, measurement data can automatically be analyzed with the iba System, e.g. for quality documentation or when machines are compared on base of characteristic values. The calculation is done interactively once and then, basing on analysis rules automatically updated for every product or fixed time intervals. The results can automatically be documented in reports or loaded in databases – no matter whether they are OEE values or product details.

Optimizing

With the web-based application ibaDaVIS the plant or machine behavior can be visualized user-specific on dashboards. The analysis delivers important results concerning the optimizing of processes and machines for different user groups.

The iba System – an open Ecosystem

If products of the iba System do not fully meet your requirements, you can also publish data recorded with iba via our Northbound interfaces and use them in your environment.

Areas of Application

It is our mission to bring transparency to the world of industrial production, power generation and energy distribution plants. Using an iba System, you can be sure that your plants and machines are captured 360° and every single process within can be 24/7 seamlessly recorded and made visible.

Troubleshooting

Failures in automated systems can lead to production downtime and inferior quality. Failure mode analysis is easily achieved for maintenance personnel that have access to the archived data.

Process Analysis

Process analysis is made easy with an iba System. Being able to quickly and efficiently analyze process data is vital to process optimization.

Quality Documentation

For documenting automated production systems and processes, quality data characteristics and calculated analytical values need to be stored in a reliable quality management system.

Power Quality

Measuring and monitoring electric power quality is a crucial tool for energy producers, grid operators, and consumers alike.

Condition Monitoring

Condition Monitoring Systems (CMS) use vibration measurement in combination with intelligent analysis procedures to detect wear and tear on mechanical components at an early stage.

Vibration Analysis

For reliable real-time monitoring of vibrations, offline analysis tools for optimization and validation are indispensable.

Digitalization

The acquisition of measurement data in machines and plants is a basic prerequisite for your digitalization strategy.

Contacts

Hiproject has a team of highly qualified professionals at your disposal to address any questions or requests.

The key contacts, awaiting your communication, are:

Sales

ibaslovenia-sales@hiproject.si

Urban Pevnik, Tel +386 31 674 797

Technical Support

ibaslovenia-support@hiproject.si

Jernej Erjavec, Tel +386 31 471 415