In the world of advanced industry, a new reality is emerging that is digitally supported, virtually based and data-accurate. This reality is called the industrial metaverse. It is no longer a question of whether it is real, but how much longer we can afford to ignore it.

What is the industrial metaverse anyway?

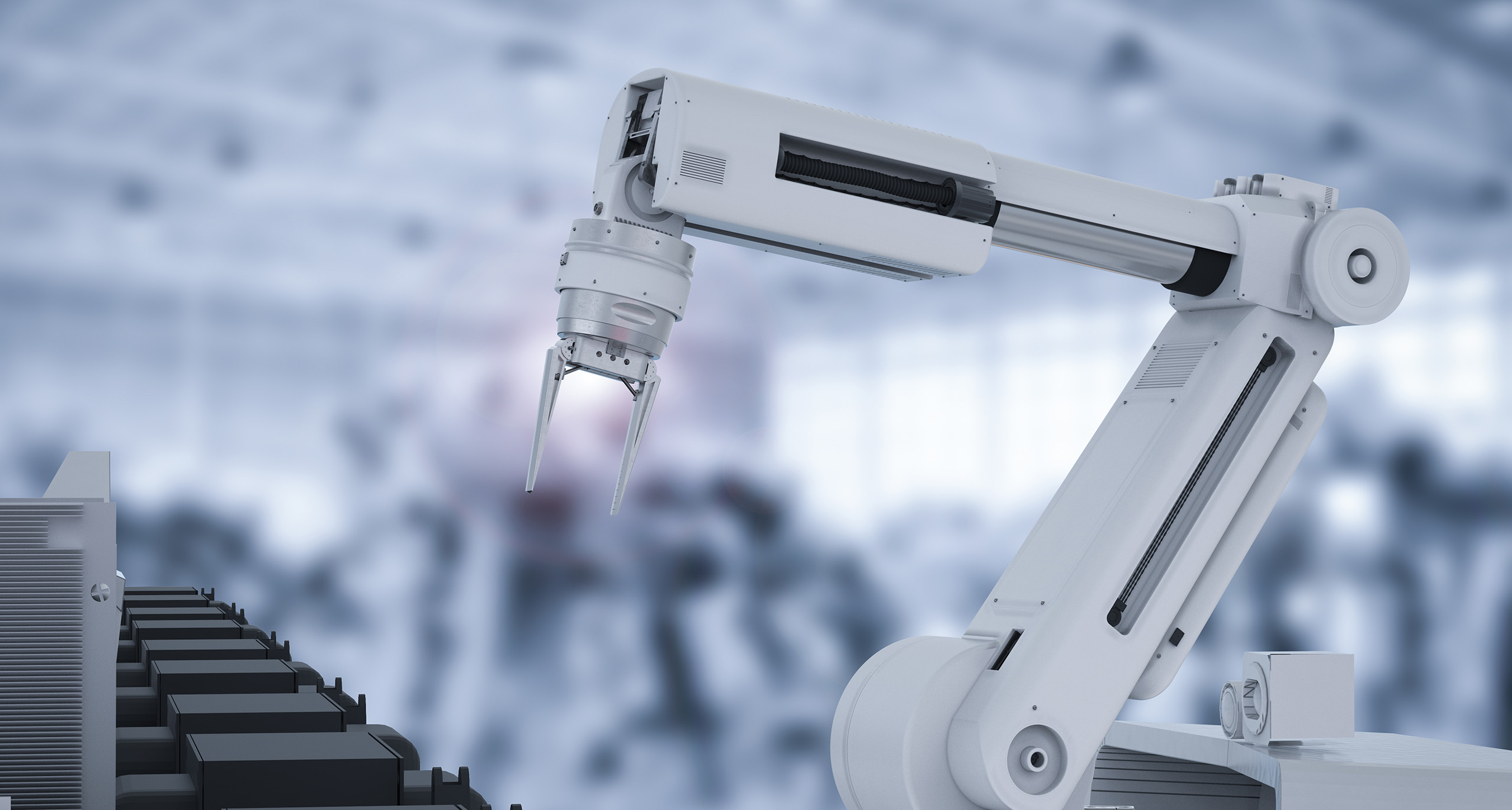

The industrial metaverse represents the next evolutionary step after digitisation, automation and Industry 4.0. It is about creating a virtual environment that closely mirrors the physical production environment using real-time data. In this digital space, companies can run simulations, test different scenarios, connect with remote teams and use artificial intelligence to analyse complex situations before these scenarios happen in the real environment.

A key role is played by so-called digital twins, which are digital replicas of machines, production lines or even entire factories. These twins allow what is happening in the physical world to be monitored, analysed and simulated in a virtual environment. A digital twin is not just a visual representation, but a system that receives data, processes it and reacts to changes in real time. In this way, companies can anticipate errors, optimise processes and speed up development without interrupting production.

Savings are measurable and visible

Metaverse in an industrial context is not something remote or experimental. Solutions already exist today to put these principles into practice. According to a 2023 McKinsey study, the use of digital twins in manufacturing leads to 30% lower maintenance costs, 50% faster product development and a 10-25% increase in productivity in just two years.

The key reasons why this is becoming important now are multifaceted. First, industrial environments are generating more and more data. Terabytes of data are generated daily in every major plant, but without proper analytics and context, this data remains unutilised. The industrial metaverse allows us to use this data to improve decision-making and responsiveness in real time.

Second, companies are facing pressure for energy and environmental efficiency. Any optimisation, whether in heating, cooling, energy consumption or logistics, has a direct impact on the environment and costs. Virtual testing of measures before implementing them in the real world means fewer wrong decisions and greater accountability.

Thirdly, staff shortages, especially of technically qualified staff, are forcing companies to look for new approaches to training. The industrial metaverse enables safe, fast and realistic learning in a simulated environment, without endangering people or production assets. This is particularly important in industries where mistakes can be costly or dangerous.

How to get started with metaverse and digital twins?

Preparing for the introduction of an industrial metaverse starts with the development of the data infrastructure. Systems are needed to capture and interpret data in real time. Then, the integration of artificial intelligence must be ensured to analyse this data and turn it into actionable information. Last but not least, a culture that fosters digital readiness needs to be established, both in management and in operational teams.

We are already ready

Today, HIProject is heavily involved in the preparation of the core components. With exclusive representation for the iba system, which enables millisecond capture of process data, our own development of artificially intelligent models and a clear Industry 5.0 philosophy that puts people at the centre, we are enabling a digital transformation that can also organically evolve in a simulation direction.

The industrial metaverse is therefore not an abstract future. It is a logical continuation of current technological processes. It gives industry more than a virtual environment, it gives it a strategic advantage. It is a tool to lead the industry into the next decade with fewer mistakes, less waste and more knowledge.

Businesses that understand the power of simulation, foresight and collaboration in virtual environments will be ready for the challenges of the new era.

Interested in getting started with digital doublethink? Let’s talk. First comes data transparency. Then simulation. And then the industry of the future.